We process thermoplastic and thermoset plastics with precision. Our specialities include high-temperature materials and multi-component injection moulding as well as the overmoulding of inserts and metal parts or with the tightest tolerances for high mechanical requirements and the production of crystal-clear or moulded parts with high surface requirements. Put us to the test!

Plastic injection moulding & component assembly – your full-service provider for precision parts

High-precision plastics processing: perfect processes for the best quality

Technology balance

Material knowledge

Assembly excellence

Premium surface

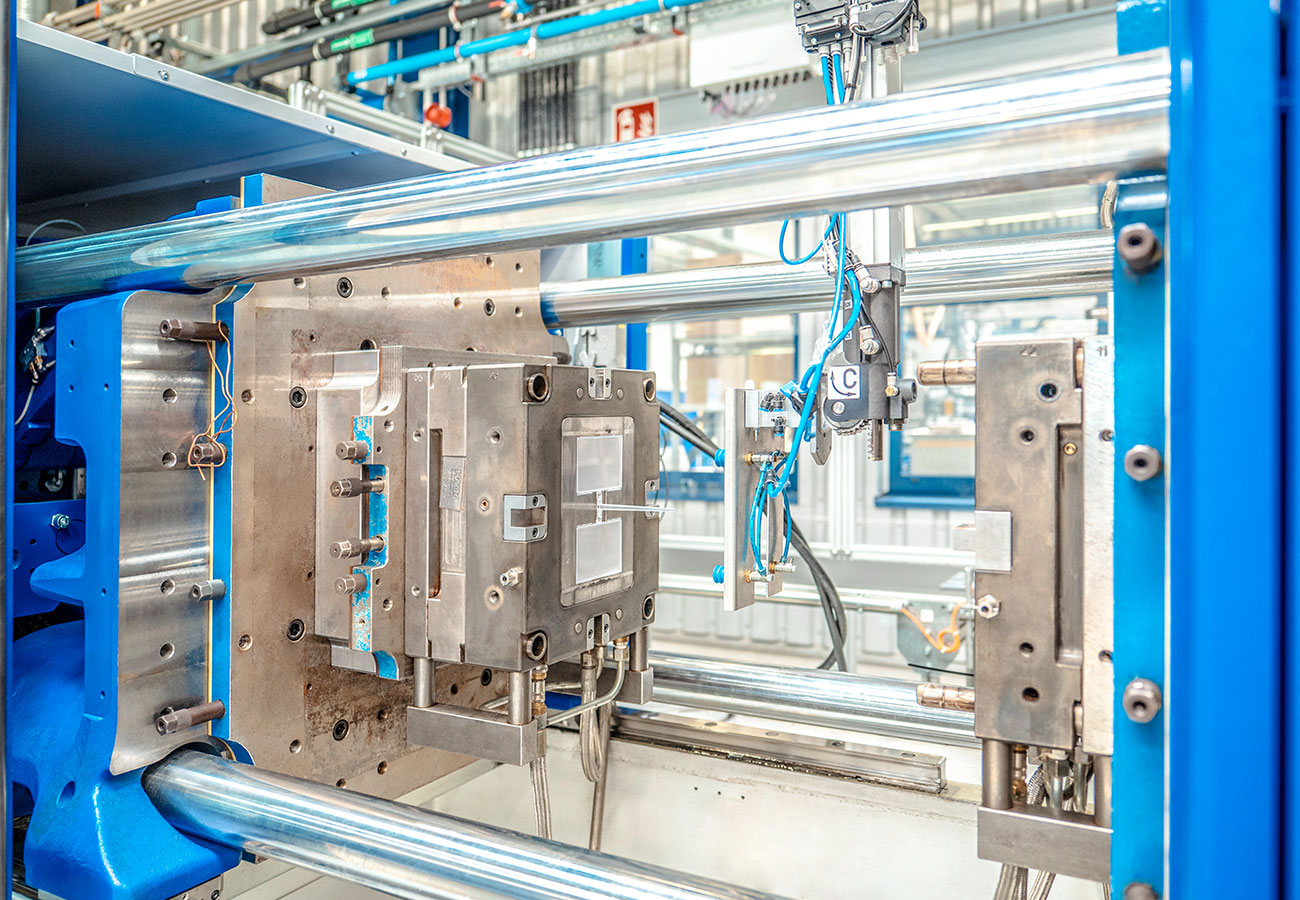

Only those who perfectly optimise the parameters of plastic injection moulding will achieve the best possible result. Dosing, injection, holding pressure, tempering and cooling as well as demoulding must be perfectly balanced.

Some plastic parts only take on their final shape through appropriate reworking or further processing. This follow-up work is coordinated with our customers on a part-specific basis in order to ensure the best and most cost-effective production.

You can assemble parts somehow or join them together with care: Torques, loads, rubbing and pressure can also leave unwanted marks during assembly. Unless you are experienced and think ahead.