Hybrid parts made of plastic & metal - maximum stability & precision

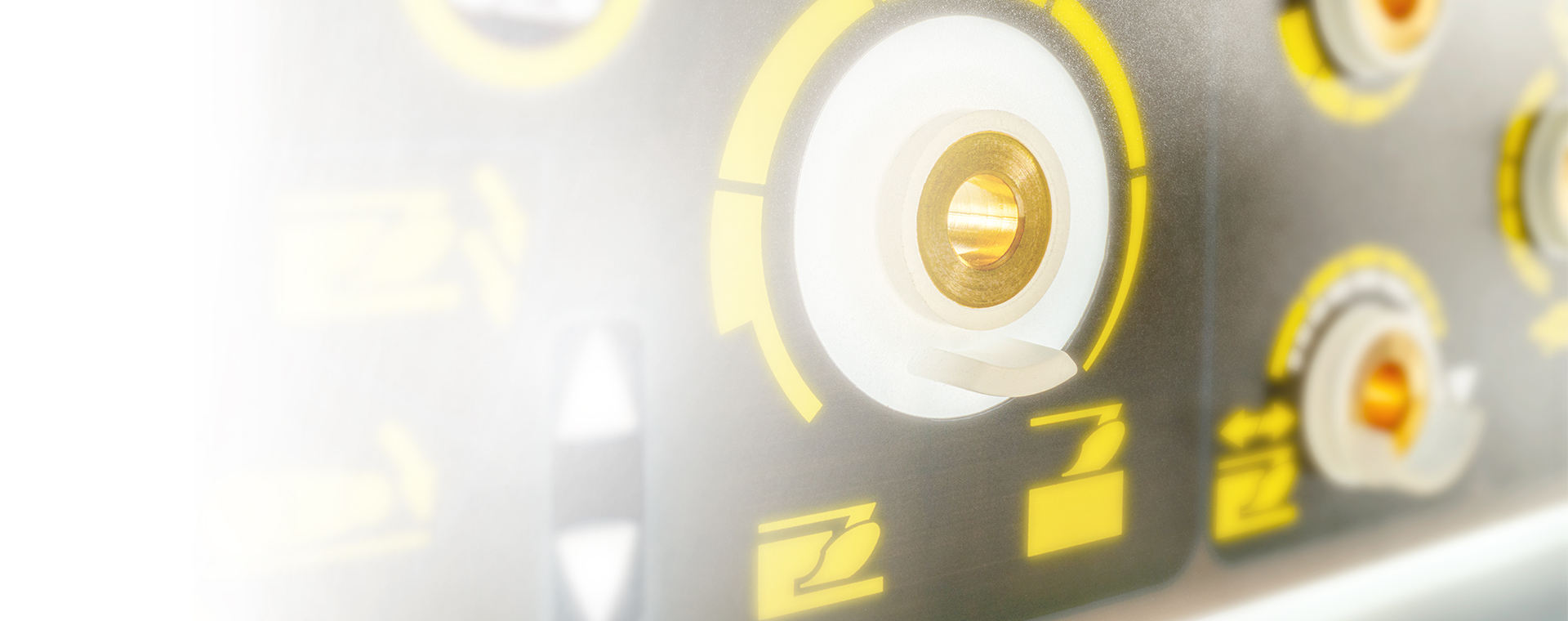

Hybrid parts have a wide range of applications, and their design possibilities are equally diverse: In situations where force transmission requires precision, metal bearings are an optimal choice due to their low wear resistance. In scenarios where signals need to be transmitted, the use of cables and connectors that are permanently connected to a component is essential. In cases where a screw connection is subject to mechanical stress and could potentially fail due to tearing in the plastic component, the combination of plastic and metal provides a robust solution. Our specialism lies in the design of injection moulding tools, which are equipped with the necessary metal components prior to the injection moulding process. These components are then cast into the desired plastic. This ensures a precise fit for shaft bearings, plugs, pins or threads. In addition, this method enhances the durability of the component as a whole in comparison with alternative techniques, such as press-fitting, because no mechanical forces are applied to the part.

A distinction is made between insert technology and outsert technology. In the process of insert moulding, metal components are integrated into a part that is primarily composed of plastic. In the process of outsert moulding, the component consists primarily of metal onto which plastic elements are injection moulded.

Hybrid components have been in existence for many decades: what began with components for Siedle has also established itself over the years for various customers from all other sectors. We overmould a wide variety of inserts using both thermoplastics and thermosets. Right from the development phase, we provide advice to our customers on the optimal plastic to meet the component-specific challenge in order to achieve the most cost-effective production of their products.

Fields of application:

- Sensors

- Electromechanics

- Electronics

- Medical technology

- Automotive

- Household technology