Customised plastic parts for consumer & mechanical engineering - flexible & precise

The consumer and mechanical engineering sectors are leading industries in Germany and Europe. As production processes become increasingly digitalised and sensorised and products become more customised, the demands placed on plastic parts and their variability are also growing. The industry is characterised by small and medium quantities with very high requirements for the design, mechanical strength and surface quality of the required components. This increases the challenge for suppliers in the plastics sector to react quickly and flexibly with the necessary expertise. We support customers in these market segments right from the development phase and subsequently also produce small and medium-sized series for clients in this sector.

Successful plastics solutions for consumer & mechanical engineering – best practice examples

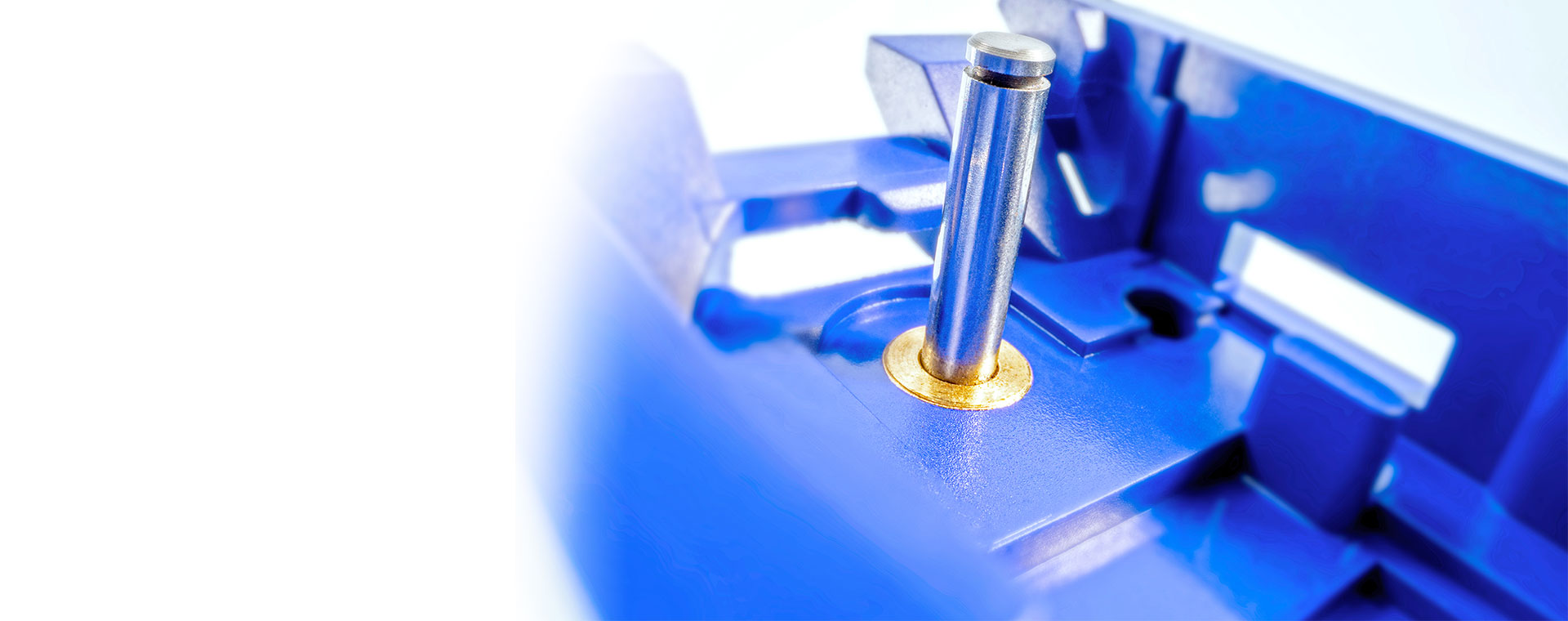

Film back injection moulding

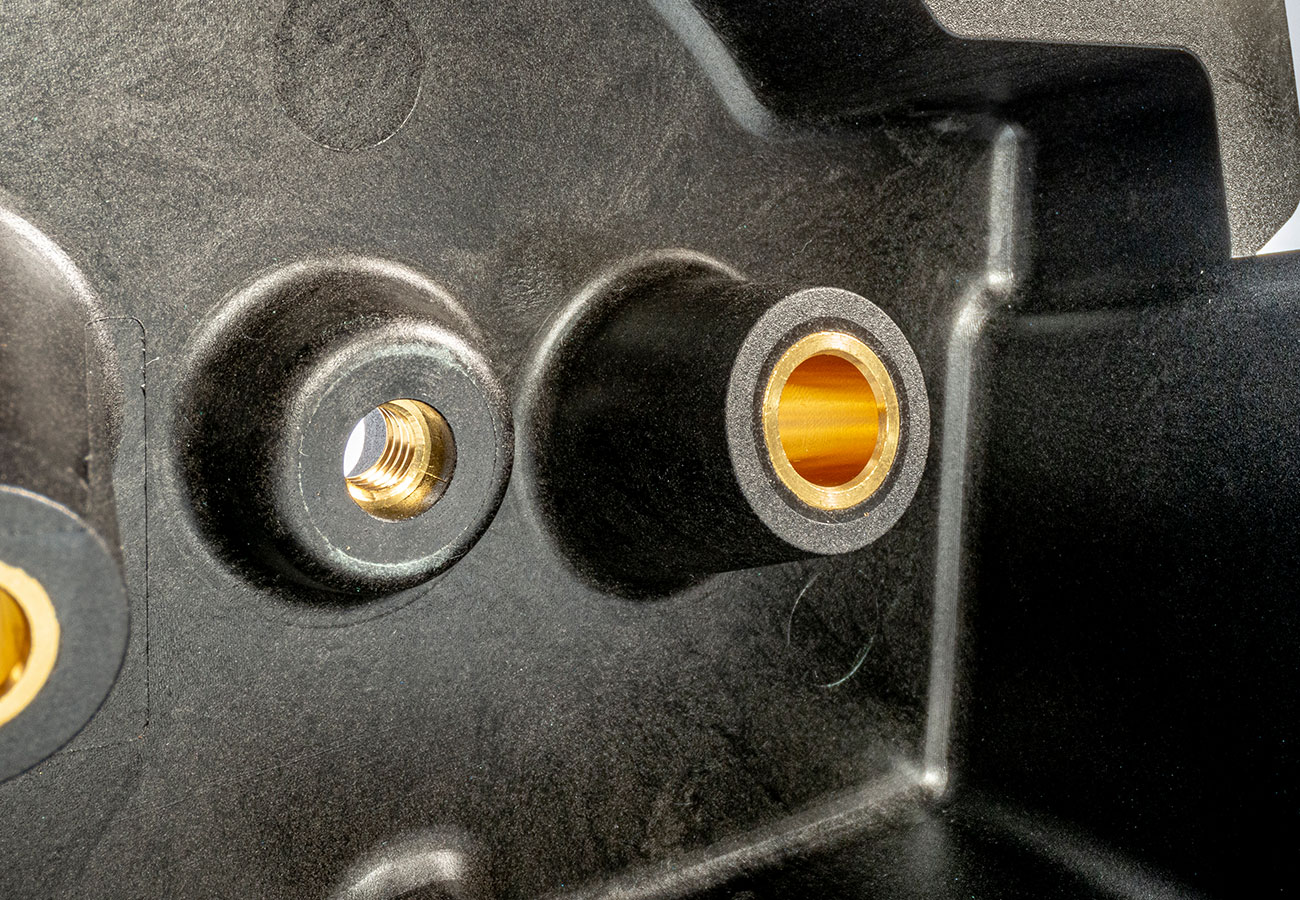

Stable and resilient

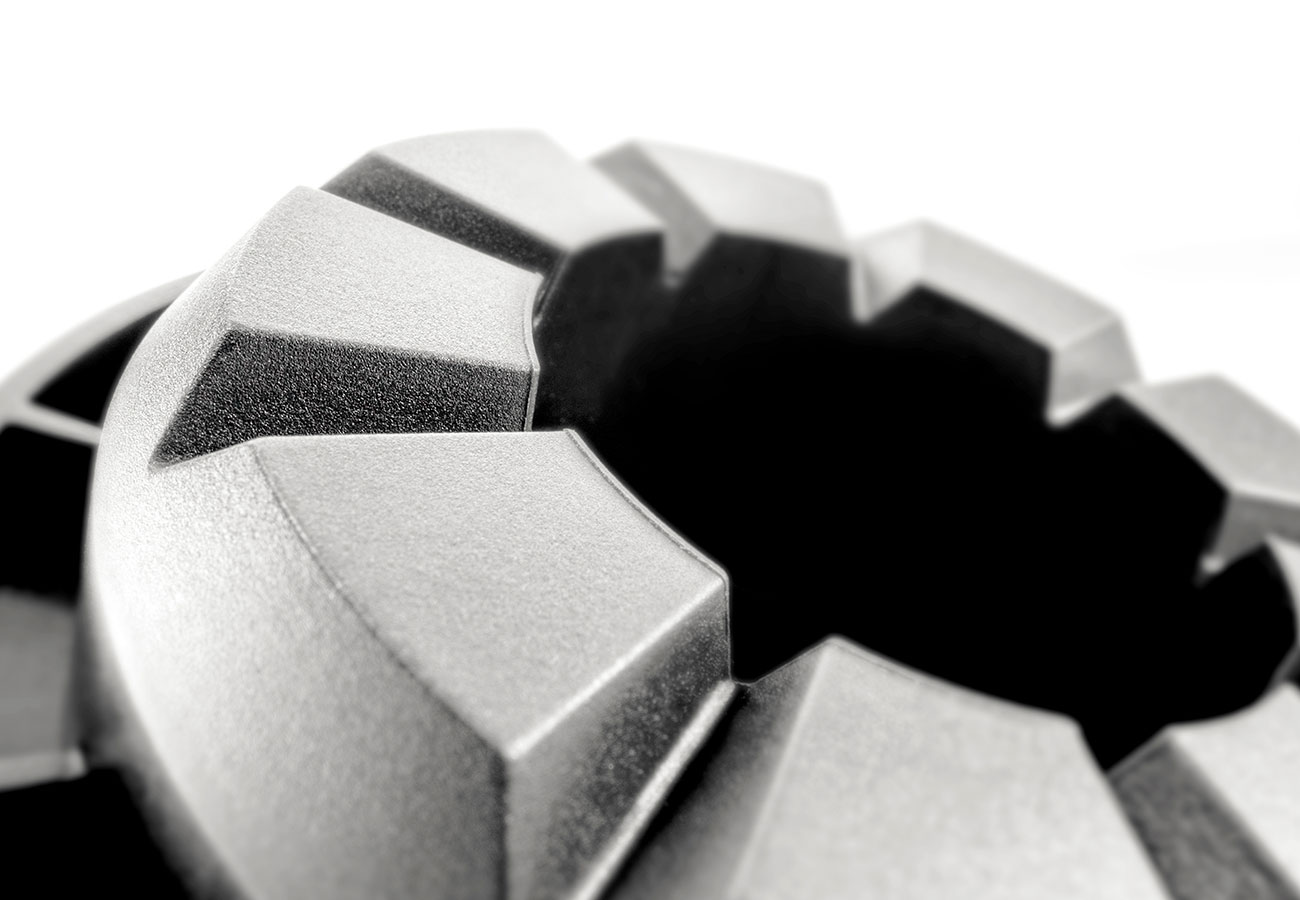

From thick to thin with glass fibre reinforcement

Solid fluid guidance

Control panels must not only be effective and stylish, but also durable – and they should be easily adaptable to different device types within the same series. Just like this translucent control panel, which is manufactured using a back-moulding technique, in which different insert foils are utilised.

Find out more

Where the properties of plastics are not sufficient, hybrid parts like this one are a perfect mix: stable lightweight construction made of high-performance thermoplastic with brass bearings for high durability.

Find out more

Thanks to our extensive process expertise, we can cope with extreme wall thicknesses and very high surface requirements in glass fibre-reinforced thermoplastic for this part.

Find out more

Burr-free transitions in fluid-carrying areas were just one of many requirements for this component from the hydraulics sector. We were involved in the development right from the start and found the perfect solution.

Find out more