Innovative plastic parts for the automotive industry - lightweight construction & precision for motor vehicles

The automotive industry is the technological driver for new processes, new technologies and new materials. The topics of lightweight construction, sensorisation and increasing demands on the performance of plastics are the future challenges for suppliers. Thanks to our many years of experience in working with high-performance thermoplastics and thermosets, as well as the design and production of technically complex plastic parts and plastic-metal hybrid components, we are ideally placed to fulfil the upcoming requirements for components. We are pleased to offer our know-how as early as the design process in order to optimise costs in production. This can be achieved through process-friendly design or through dialogue on usable plastics and tool-optimised details in the component. We invite you to experience the full range of our services for yourself.!

Successful plastics solutions in the automotive sector – best practice examples

Housing cover with seal

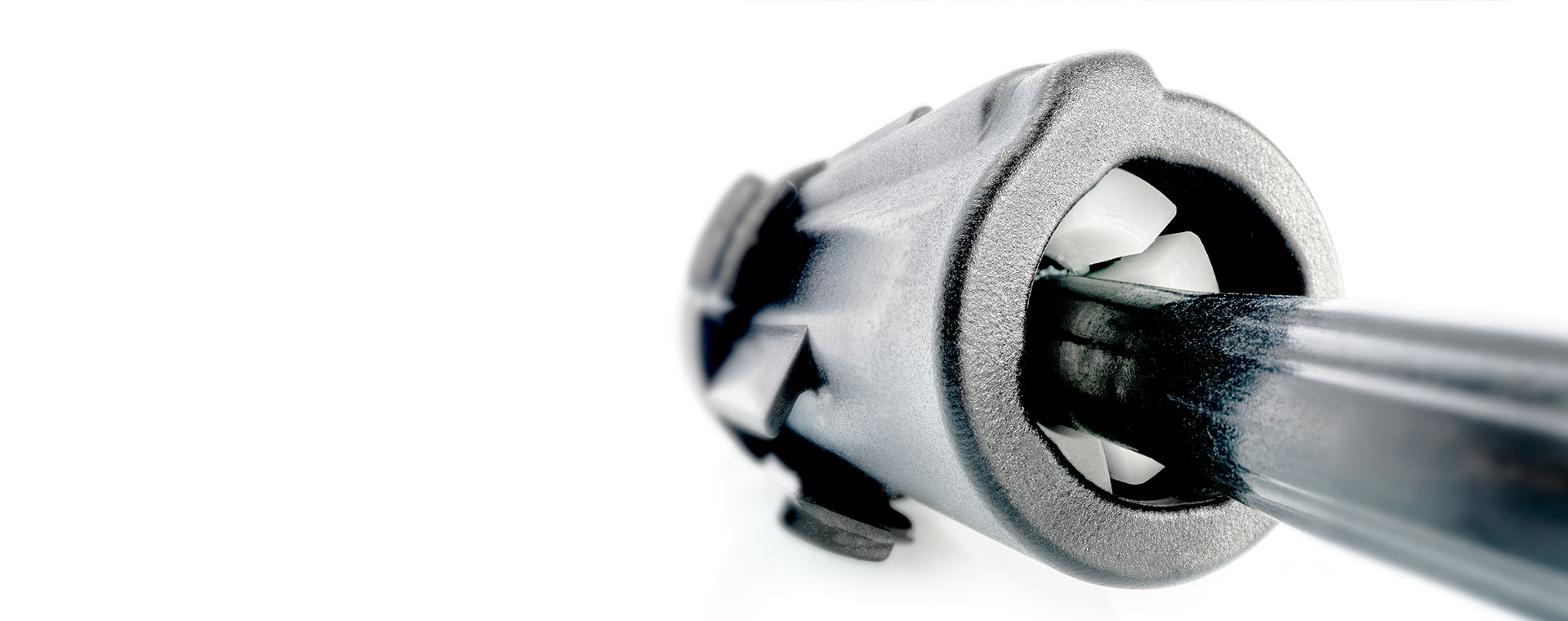

Clutch actuator assembly

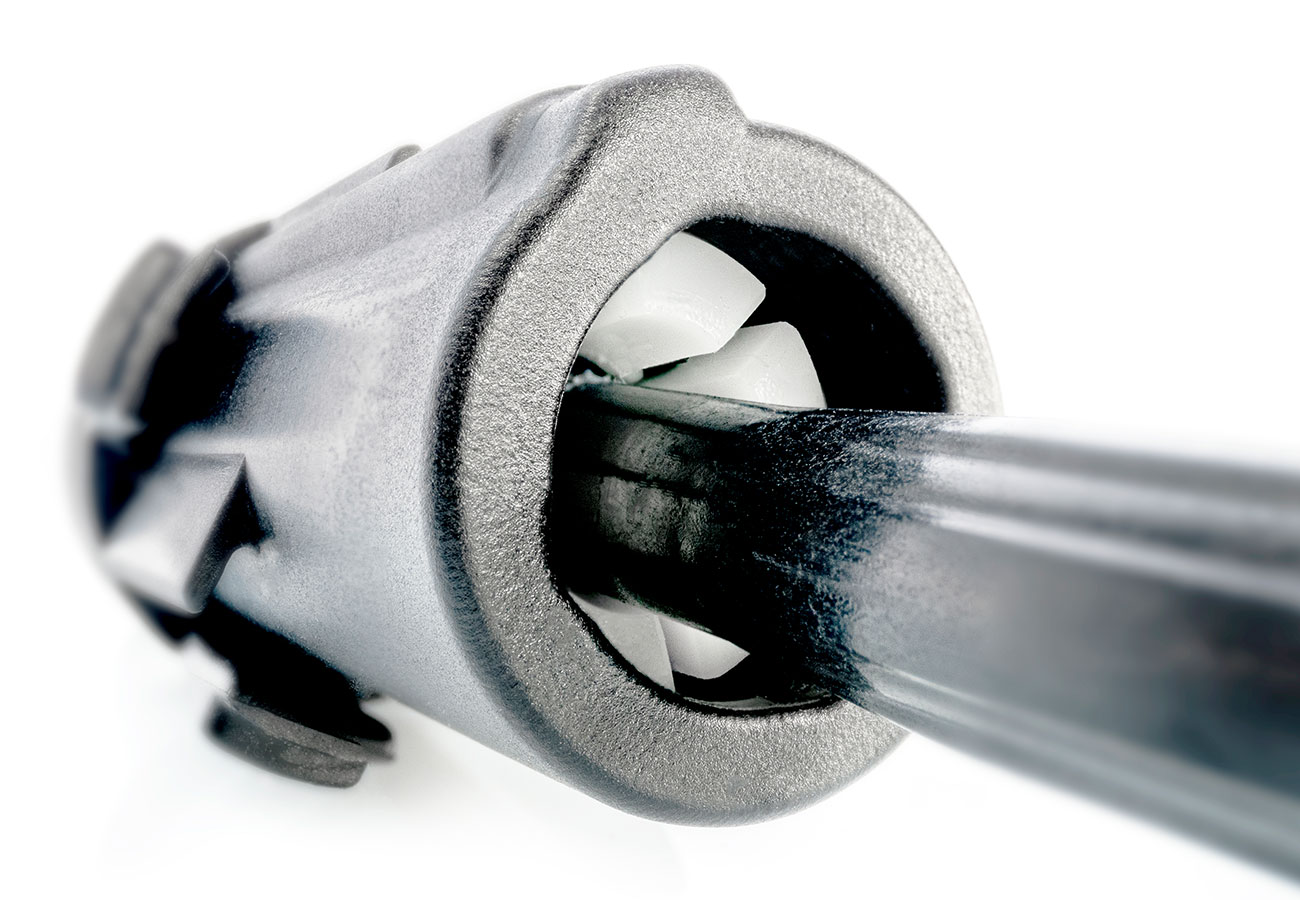

Metal replacement actuator piston

Shorter process: To optimise the sealing of a housing cover, we designed the part using multi-component injection moulding and injected an elastomer seal into the part in a single process.

Find out more

With our thermoset piston and the associated operating segment, we are replacing a heavier metal part for the reliable and durable operation of a dual clutch transmission – lightweight construction starts with the details!

Find out more

With extreme requirements for surfaces and dimensional accuracy in the range of 5 µm maximum, this part is proof of the precision that is possible in thermoset.

Find out more